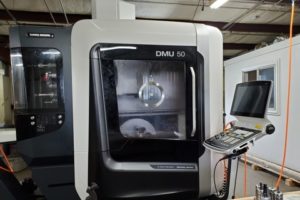

WIPCO in Livingston, Texas, is proud to offer precision machining of parts made from various materials. Our shop is equipped with state-of-the-art machines, such as CNC Lathes and Mills that our highly skilled professionals use to machine your parts.

Our expertise in high-quality precision machining allows us to produce the parts you require in a timely manner. Our shop features the following machines:

- 1X FanUC Robodrill CNC 4-axis mill

- 1X FanUC Robodrill CNC 5-axis mill

- 1 DMG Mori DMU 50 5 Axis Mill

- 1 Haas VF-4 4 Axis CNC Mill

- 1 DMG Mori NLX 2000 Multi-Spindle Lathe

- 1 DMG Mori NLX 2500 Multi-Spindle Lathe

- 1 DMG Mori Gildemeister 32/8 Screw Machine

- 1 Haas UMC 750 5 Axis Mill

- 1 Samsung SL4500 Lathe

- 5 Haas SL10 CNC Lathes

- 1 Haas SL20 CNC Lathe

- 1 Haas SL30 CNC Lathe

- 1 Hardinge Super Precision Lathe

- Various Manual Lathes & Mills

- Fully Automated Cosen Saw, Model C-260NC

- Cyclone Bead Blaster

We heavily emphasize manufacturing quality control and quality assurance. Through a variety of methods, tools, and equipment – we ensure that all parts are produced in accordance to our customers prints and specifications.

For more information on our equipment and manufacturing capabilities, view WIPCO’s Capabilities Statement .