Large part machining is necessary for parts that are too heavy to be effectively moved by one person, or when parts cannot fit in standard parts machining equipment. This process typically involves the use of specialized tools, such as lathes, milling machines, and drills, that are capable of handling the size and weight of the workpiece. Large part machining requires a high degree of precision and accuracy to ensure that the finished components meet the required specifications. It is a crucial part of many industries, as it enables the production of high-quality, durable, and reliable parts that are essential to the operation of various machinery and equipment.

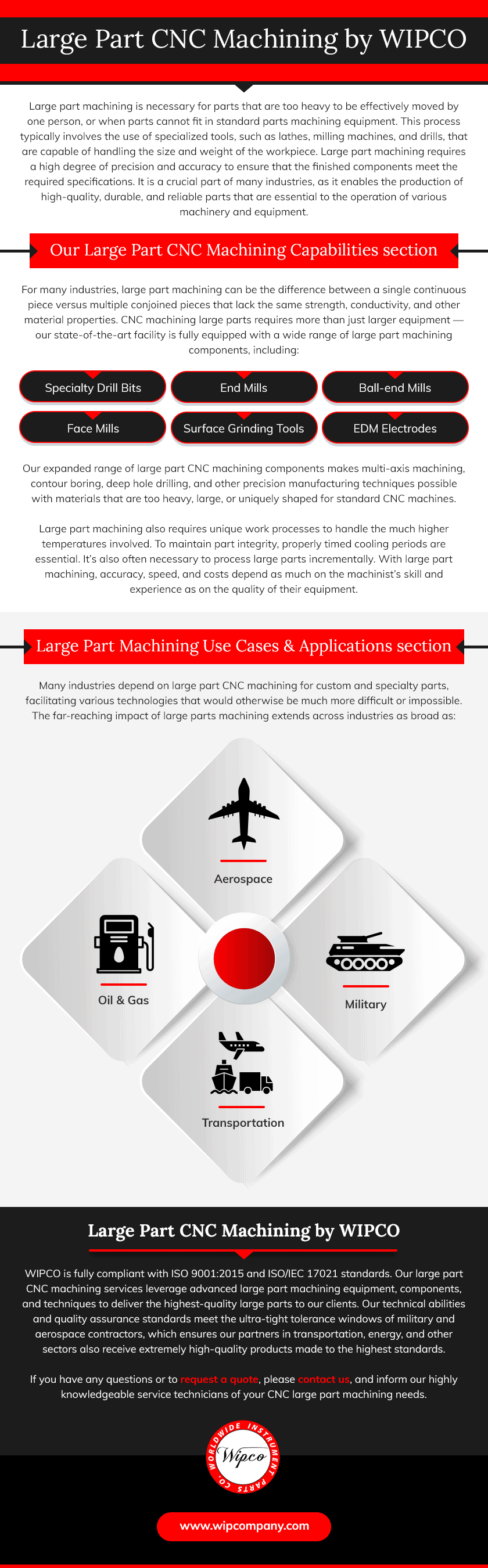

Our Large Part CNC Machining Capabilities

For many industries, large part machining can be the difference between a single continuous piece versus multiple conjoined pieces that lack the same strength, conductivity, and other material properties. CNC machining large parts requires more than just larger equipment — our state-of-the-art facility is fully equipped with a wide range of large part machining components, including:

- Specialty drill bits

- End mills

- Ball-end mills

- Face mills

- Surface grinding tools

- EDM electrodes

Our expanded range of large part CNC machining components makes multi-axis machining, contour boring, deep hole drilling, and other precision manufacturing techniques possible with materials that are too heavy, large, or uniquely shaped for standard CNC machines.

Large part machining also requires unique work processes to handle the much higher temperatures involved. To maintain part integrity, properly timed cooling periods are essential. It’s also often necessary to process large parts incrementally. With large part machining, accuracy, speed, and costs depend as much on the machinist’s skill and experience as on the quality of their equipment.

Large Part Machining Use Cases & Applications

Many industries depend on large part CNC machining for custom and specialty parts, facilitating various technologies that would otherwise be much more difficult or impossible. The far-reaching impact of large parts machining extends across industries as broad as:

- Aerospace: Hydraulic manifolds, transmissions, fuel bodies, landing gear, electrical connectors, housings, and more utilize large part machining to expand the limits of space-age technology.

- Military: From large couplers and seat frames to helicopters, missiles, and other components, the products of large part machining can be found in technologies used in every branch of the military.

- Transportation: Large part CNC machining keeps supply chains running with freight train components, large truck parts, shipping vessels, and more.

- Oil & Gas: The energy sector operates more safely and efficiently with large part items found in pipelines, refineries, oil rigs, etc.

Most industrial manufacturing, in general, has some need for large part machining. CNC large part machining ensures companies across industries receive high volumes of precision-engineered components quickly and economically.

Choosing a CNC Machining Service Provider

CNC machining providers who adhere to the most advanced quality assurance systems are able to provide consistent and reliable quality levels to their customers. Because our facility is already equipped to create components within the ultra-tight tolerance levels of international aerospace standards, even customers with less stringent requirements often receive products that exceed their expectations.

Be sure your large part CNC machining provider makes available an up-to-date ISO 9001:2015 certification. Proof of OSHA compliance, AWS Certified Welding, and any other credentials relevant to your industry are also essential to confirm before entrusting your project to a turnkey manufacturer.

Large Part CNC Machining by WIPCO

WIPCO is fully compliant with ISO 9001:2015 and ISO/IEC 17021 standards. Our large part CNC machining services leverage advanced large part machining equipment, components, and techniques to deliver the highest-quality large parts to our clients. Our technical abilities and quality assurance standards meet the ultra-tight tolerance windows of military and aerospace contractors, which ensures our partners in transportation, energy, and other sectors also receive extremely high-quality products made to the highest standards.

If you have any questions or to request a quote , please contact us , and inform our highly knowledgeable service technicians of your CNC large part machining needs.