At WIPCO, we specialize in precision CNC machining. Our 15,000 square-foot climate-controlled facility is equipped with a wide range of CNC mills, lathes, and screw machines to produce high quality parts based on customer specifications. From simple, easy to machine parts to extremely complex parts, we have the equipment and expertise to produce components for multiple industries and applications.

What Is CNC Machining?

CNC machining is an automated manufacturing process that uses pre-programmed computer software to move tools and machinery based on the specified cuts and dimensions. In CNC machining processes, speed and tooling position can be pre-programmed, allowing for predictable, repetitive cycles with little human involvement.

CNC machining is an automated manufacturing process that uses pre-programmed computer software to move tools and machinery based on the specified cuts and dimensions. In CNC machining processes, speed and tooling position can be pre-programmed, allowing for predictable, repetitive cycles with little human involvement.

Often performed using mills, lathes, and other various equipment, CNC machining begins by creating a 2D or 3D CAD drawing. This model is then translated into code and inputted into the CNC system. The operator will often perform a trial run to ensure there are no defects in the code before beginning a project. The automation and various other advantages of CNC machining make it the preferred manufacturing method for several industries.

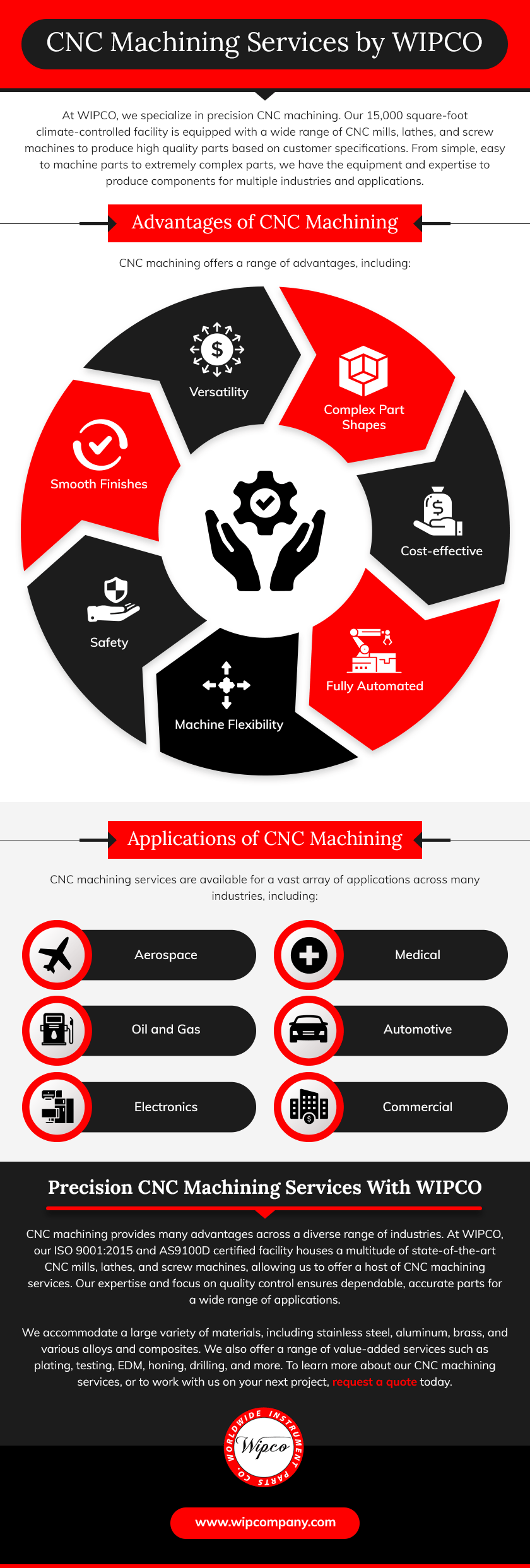

Advantages of CNC Machining

CNC machining offers a range of advantages, including:

- Complex part shapes. Because CNC machines have several axes, they can have a greater range of movement, allowing for the rapid production of more complex parts.

- Cost-effective. CNC machining lowers labor costs, reduces rework and scrap, and produces high-volume precision parts quickly, creating cost-effective parts for your customers and greater profit margins for your business.

- Fully automated. CNC machining needs only one CNC machinist to operate multiple machines at a time. Automation increases accuracy, is easily scalable, and is much faster than manual processes.

- Machine flexibility. CNC machines only require the input of new dimensions, cuts, or programs to shift to an entirely different part. They can quickly switch from an old program to a new one, allowing for greater flexibility of each machine.

- Safety. The automation provided by CNC machining minimizes workers’ risk of injury when using fast and sharp machines. CNC machines frequently have shields or transparent doors that separate the machinist from the equipment, making them much safer than manually operated machines.

- Smooth finishes. Because CNC routers and cutting tools operate with extremely sharp bits at high speeds, they produce a superior smooth and clean cut.

- Versatility. While CNC machining creates a wide variety of simple and complex components, their versatility can be increased further with additional features and accessories like automatic tooling changes and touch screens.

Applications of CNC Machining

CNC machining services are available for a vast array of applications across many industries, including:

- Aerospace. Used for producing fuel flow components, manifolds, engine mounts, bushings, landing gear, and other aircraft parts.

- Medical. Used to create precision components such as implants, orthotics, surgical instruments, electronic enclosures, and more.

- Oil and gas. Used for manufacturing parts for pipelines, rigs, and refineries, such as rods, pins, drill bits, pistons, cylinders, and valves.

- Automotive. Used to produce various automotive components, including cylinder blocks, valves, axles, gearboxes, dashboard panels, and gas gauges.

- Electronics. Used to create various electronic components such as heat sinks, RFI shields, amplifier housings, and electrical insulation.

- Commercial. CNC machining offers easy prototyping, enabling new product development for high volume, repeatable, cost-efficient parts.

Precision CNC Machining Services With WIPCO

CNC machining provides many advantages across a diverse range of industries. At WIPCO, our ISO 9001:2015 and AS9100D certified facility houses a multitude of state-of-the-art CNC mills, lathes, and screw machines, allowing us to offer a host of CNC machining services. Our expertise and focus on quality control ensures dependable, accurate parts for a wide range of applications.

We accommodate a large variety of materials, including stainless steel, aluminum, brass, and various alloys and composites. We also offer a range of value-added services such as plating, testing, EDM, honing, drilling, and more. To learn more about our CNC machining services, or to work with us on your next project, request a quote today.