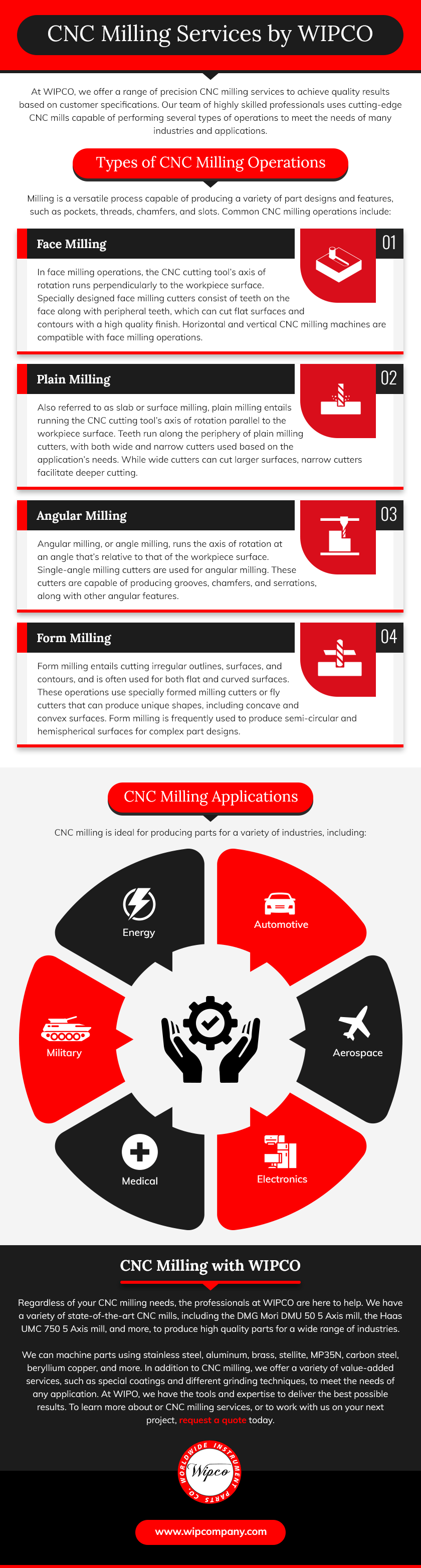

At WIPCO, we offer a range of precision CNC milling services to achieve quality results based on customer specifications. Our team of highly skilled professionals uses cutting-edge CNC mills capable of performing several types of operations to meet the needs of many industries and applications.

What is CNC Milling?

The CNC milling process begins with designing a CAD model, which is a 2D or 3D part design that serves as a template. The CAD design is then converted into a designated CNC program to produce the part from base materials. Before running the CNC program, operators prep the CNC milling machine by setting up the workpiece and work surface. Once the machine is set up, the operator begins executing the designated milling operation to produce the completed part based on the CAD design.

Types of CNC Milling Operations

Milling is a versatile process capable of producing a variety of part designs and features, such as pockets, threads, chamfers, and slots. Common CNC milling operations include:

Face Milling

In face milling operations, the CNC cutting tool’s axis of rotation runs perpendicularly to the workpiece surface. Specially designed face milling cutters consist of teeth on the face along with peripheral teeth, which can cut flat surfaces and contours with a high quality finish. Horizontal and vertical CNC milling machines are compatible with face milling operations.

Plain Milling

Also referred to as slab or surface milling, plain milling entails running the CNC cutting tool’s axis of rotation parallel to the workpiece surface. Teeth run along the periphery of plain milling cutters, with both wide and narrow cutters used based on the application’s needs. While wide cutters can cut larger surfaces, narrow cutters facilitate deeper cutting.

Angular Milling

Angular milling, or angle milling, runs the axis of rotation at an angle that’s relative to that of the workpiece surface. Single-angle milling cutters are used for angular milling. These cutters are capable of producing grooves, chamfers, and serrations, along with other angular features.

Form Milling

Form milling entails cutting irregular outlines, surfaces, and contours, and is often used for both flat and curved surfaces. These operations use specially formed milling cutters or fly cutters that can produce unique shapes, including concave and convex surfaces. Form milling is frequently used to produce semi-circular and hemispherical surfaces for complex part designs.

In addition to these core operations, other types of specialized milling operations include straddle, gang, profile, and gear milling, each of which perform their own unique tasks suitable for many applications.

CNC Milling Applications

CNC milling is ideal for producing parts for a variety of industries, including:

- Automotive. CNC milling is used to create parts for vehicles such as piston rods, pumps, flywheels, drive housings, engine blocks, and cylinders.

- Aerospace. CNC milling is capable of producing parts with hard metals and other specialty materials necessary for the aerospace industry. Milling is crucial for the production of steering components and other aircraft parts.

- Electronics. Precision CNC milling can create tiny, complex parts needed for motherboards and other electronic equipment.

- Medical. CNC milling is used to create high tech medical equipment and tools, such as prosthetics, hip stems and cups, and cavity molds.

- Military. CNC milling is capable of producing parts that meet the precision requirements for the military. It is used to create components for military technology, gun parts, and more.

- Energy. CNC milling is used to create gears, valves, fuel pumps, and other elaborate components for air, hydroelectric, and nuclear energy applications.

CNC Milling with WIPCO

Regardless of your CNC milling needs, the professionals at WIPCO are here to help. We have a variety of state-of-the-art CNC mills, including the DMG Mori DMU 50 5 Axis mill, the Haas UMC 750 5 Axis mill, and more, to produce high quality parts for a wide range of industries.

We can machine parts using stainless steel, aluminum, brass, stellite, MP35N, carbon steel, beryllium copper, and more. In addition to CNC milling, we offer a variety of value-added services, such as special coatings and different grinding techniques, to meet the needs of any application. At WIPO, we have the tools and expertise to deliver the best possible results. To learn more about or CNC milling services, or to work with us on your next project, request a quote today.