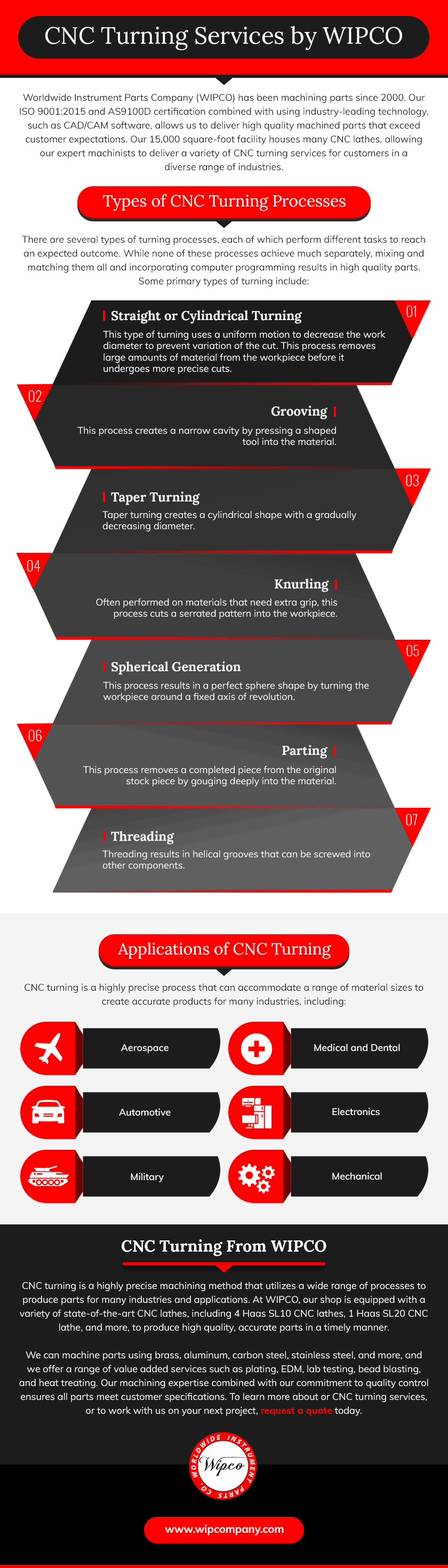

Worldwide Instrument Parts Company (WIPCO) has been machining parts since 2000. Our ISO 9001:2015 and AS9100D certification combined with using industry-leading technology, such as CAD/CAM software, allows us to deliver high quality machined parts that exceed customer expectations. Our 15,000 square-foot facility houses many CNC lathes, allowing our expert machinists to deliver a variety of CNC turning services for customers in a diverse range of industries.

What Is CNC Turning?

In the CNC turning process, otherwise known as subtractive machining, a chuck holds a bar of material, such as plastic or metal, in place. The piece rotates on a lathe, allowing a computer-controlled turret with attached tooling to cut the material into a specified shape based on programmed instructions. The more tools a turret can hold, the more complex options are available for the part. CNC lathes and turning centers can utilize a variety of processes to create different end results.

In the CNC turning process, otherwise known as subtractive machining, a chuck holds a bar of material, such as plastic or metal, in place. The piece rotates on a lathe, allowing a computer-controlled turret with attached tooling to cut the material into a specified shape based on programmed instructions. The more tools a turret can hold, the more complex options are available for the part. CNC lathes and turning centers can utilize a variety of processes to create different end results.

Types of CNC Turning Processes

There are several types of turning processes, each of which perform different tasks to reach an expected outcome. While none of these processes achieve much separately, mixing and matching them all and incorporating computer programming results in high quality parts. Some primary types of turning include:

- Straight or cylindrical turning. This type of turning uses a uniform motion to decrease the work diameter to prevent variation of the cut. This process removes large amounts of material from the workpiece before it undergoes more precise cuts.

- Grooving. This process creates a narrow cavity by pressing a shaped tool into the material.

- Taper turning. Taper turning creates a cylindrical shape with a gradually decreasing diameter.

- Knurling. Often performed on materials that need extra grip, this process cuts a serrated pattern into the workpiece.

- Spherical generation. This process results in a perfect sphere shape by turning the workpiece around a fixed axis of revolution.

- Parting. This process removes a completed piece from the original stock piece by gouging deeply into the material.

- Threading. Threading results in helical grooves that can be screwed into other components.

Applications of CNC Turning

CNC turning is a highly precise process that can accommodate a range of material sizes to create accurate products for many industries, including:

- Aerospace. CNC turning is critical to the manufacturing of high-precision parts, engines, and aircraft bodies for the aviation industry.

- Medical and dental. Turning produces precise measurements, points, and angles for tools and instruments used in the dental and medical field.

- Automotive. CNC turning quickly creates precise shafts, valves, and other parts for consumer, commercial, and defense vehicles to keep up with industry demands.

- Electronics. CNC turning is capable of producing the highly complex and precise parts needed to manufacture computers and other electronics.

- Military. Turning can machine parts to high-standards with precise tolerances for military vehicles, avionics, and other military equipment.

- Mechanical. CNC turning is capable of producing machine parts, such as screws, motor shafts, and more, for the mechanical industry that meet necessary technical specifications.

The highly precise nature of CNC turning also makes it suitable for woodworking, certain electrical applications, and electrical discharge machining (EDM).

CNC Turning From WIPCO

CNC turning is a highly precise machining method that utilizes a wide range of processes to produce parts for many industries and applications. At WIPCO, our shop is equipped with a variety of state-of-the-art CNC lathes, including 4 Haas SL10 CNC lathes, 1 Haas SL20 CNC lathe, and more, to produce high quality, accurate parts in a timely manner.

We can machine parts using brass, aluminum, carbon steel, stainless steel, and more, and we offer a range of value added services such as plating, EDM, lab testing, bead blasting, and heat treating. Our machining expertise combined with our commitment to quality control ensures all parts meet customer specifications. To learn more about or CNC turning services, or to work with us on your next project, request a quote today.