Stainless steel is a broad term that applies to many types of steel known for their corrosion resistance. This material is made up of chromium, iron, and often other alloying elements such as molybdenum, nickel, and other metals. To be considered stainless steel, the steel must contain at least 10.5% chromium, as this composition is what prevents rust formation and delivers heat-resistant properties.

Although stainless steel’s main benefit is corrosion resistance, it offers a wide range of other advantages, including:

- Low and high temperature resistance

- Recyclable

- Long service life

- Easily fabricated

- Durable and strong

- Aesthetic appearance

- Cost-effective

These benefits make stainless steel a popular choice for machining services. At Worldwide Instrument Parts Company, Inc. (WIPCO), we offer quality stainless steel machining services to deliver a range of parts for industries such as medical, aerospace, oil and gas, and more.

Stainless Steel Machining Services

As a specialty manufacturer based in Livingston, Texas, WIPCO proudly offers precision stainless steel machining services. We carry a variety of stainless steel grades from the 300 series, 400 series, and 17-4, and our shop is equipped with state-of-the-art machinery operated by skilled professionals. From washers to actuators, valve components, and other highly complex parts, our clients rely on our stainless steel machining services to create stainless steel parts for a variety of applications.

To complete your entire project in-house, we offer value-added services like coatings and special grinding techniques, third-party testing, tensile testing, and more. Our turnkey solutions simplify and streamline the manufacturing process, helping you save time, money, and hassle.

WIPCO is classified under NAICS Codes 332710 for Machine Shops and 336412 for Aircraft Engine and Engine Parts Manufacturing, and we hold ISO 9001:2015 and AS 9110D certifications.

Types of Stainless Steel

Types of Stainless Steel

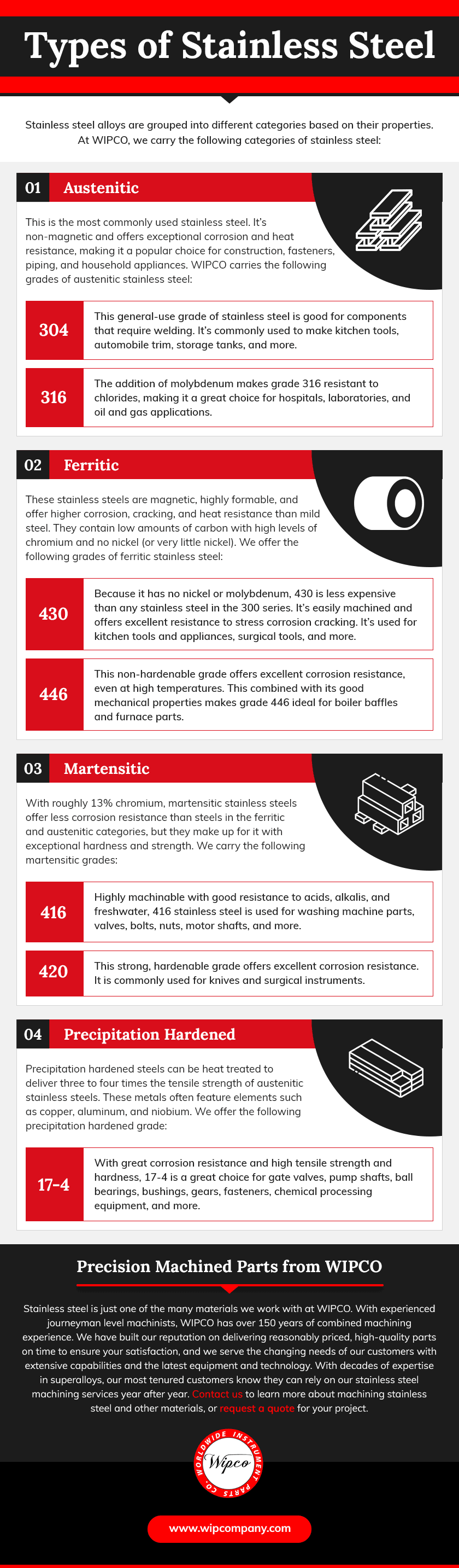

Stainless steel alloys are grouped into different categories based on their properties. At WIPCO, we carry the following categories of stainless steel:

Austenitic

This is the most commonly used stainless steel. It’s non-magnetic and offers exceptional corrosion and heat resistance, making it a popular choice for construction, fasteners, piping, and household appliances. WIPCO carries the following grades of austenitic stainless steel:

- 304. This general-use grade of stainless steel is good for components that require welding. It’s commonly used to make kitchen tools, automobile trim, storage tanks, and more.

- 316. The addition of molybdenum makes grade 316 resistant to chlorides, making it a great choice for hospitals, laboratories, and oil and gas applications.

Ferritic

These stainless steels are magnetic, highly formable, and offer higher corrosion, cracking, and heat resistance than mild steel. They contain low amounts of carbon with high levels of chromium and no nickel (or very little nickel). We offer the following grades of ferritic stainless steel:

- 430. Because it has no nickel or molybdenum, 430 is less expensive than any stainless steel in the 300 series. It’s easily machined and offers excellent resistance to stress corrosion cracking. It’s used for kitchen tools and appliances, surgical tools, and more.

- 446. This non-hardenable grade offers excellent corrosion resistance, even at high temperatures. This combined with its good mechanical properties makes grade 446 ideal for boiler baffles and furnace parts.

Martensitic

With roughly 13% chromium, martensitic stainless steels offer less corrosion resistance than steels in the ferritic and austenitic categories, but they make up for it with exceptional hardness and strength. We carry the following martensitic grades:

- 416. Highly machinable with good resistance to acids, alkalis, and freshwater, 416 stainless steel is used for washing machine parts, valves, bolts, nuts, motor shafts, and more.

- 420. This strong, hardenable grade offers excellent corrosion resistance. It is commonly used for knives and surgical instruments.

Precipitation Hardened

Precipitation hardened steels can be heat treated to deliver three to four times the tensile strength of austenitic stainless steels. These metals often feature elements such as copper, aluminum, and niobium. We offer the following precipitation hardened grade:

- 17-4. With great corrosion resistance and high tensile strength and hardness, 17-4 is a great choice for gate valves, pump shafts, ball bearings, bushings, gears, fasteners, chemical processing equipment, and more.

Precision Machined Parts from WIPCO

Stainless steel is just one of the many materials we work with at WIPCO. With experienced journeyman level machinists, WIPCO has over 150 years of combined machining experience. We have built our reputation on delivering reasonably priced, high-quality parts on time to ensure your satisfaction, and we serve the changing needs of our customers with extensive capabilities and the latest equipment and technology. With decades of expertise in superalloys, our most tenured customers know they can rely on our stainless steel machining services year after year. Contact us to learn more about machining stainless steel and other materials, or request a quote for your project.