Machine shops that produce custom components must factor in several considerations when performing small and large part machining services. Each custom product contains many components that must each be produced in a low volume. A new CNC program for each part must be created from scratch to make developing new products easier. At Worldwide Instrument Parts Company (WIPCO), we machine small to large custom precision components. Read on to learn more about custom machined parts and the services we offer.

What Are Machined Parts?

What Are Machined Parts?

Found in nearly every aspect of daily life, machined parts are produced using subtractive manufacturing techniques. This means a computer numerical control (CNC) machine, such as a mill or lathe, removes sections from a piece of raw material, called a blank, until the final component shape is revealed. Examples of machined parts range from metal aircraft engine fasteners to the tools used to assemble aircraft. Manufacturing custom machined parts requires quick and cost-effective techniques.

CNC Machining of Custom Parts

Mass production differs greatly from low-volume production. In recent years, increasing demand for custom parts has expanded the popularity of custom low-volume CNC machining. Developing more efficient and flexible manufacturing systems is critical for companies that offer machining services. New tool mechanisms allow for the installation of multiple tools on a lathe, reducing the total production time by eliminating the need to pause and switch out tools.

Large metal parts are typically machined using a 2- to 4- axis machining process, such as CNC milling, grinding, or turning. These processes achieve unparalleled precision even for the most intricate parts. CNC machining facilitates the production of a large number of unique parts at affordable prices.

Custom CNC Parts

At WIPCO, we offer a wide variety of machining services to ensure the unique needs of each project are met. From the conception stage until final component delivery, our team of expert engineers can guide your project to success. In addition to conventional CNC turning, drilling, milling, and sawing services, we also provide specialty grinding and part-making processes. When needed, we also provide heat treating, plating, welding, painting, and inspection services. Our comprehensive capabilities ensure cost certainty and quality control for every order.

Applications

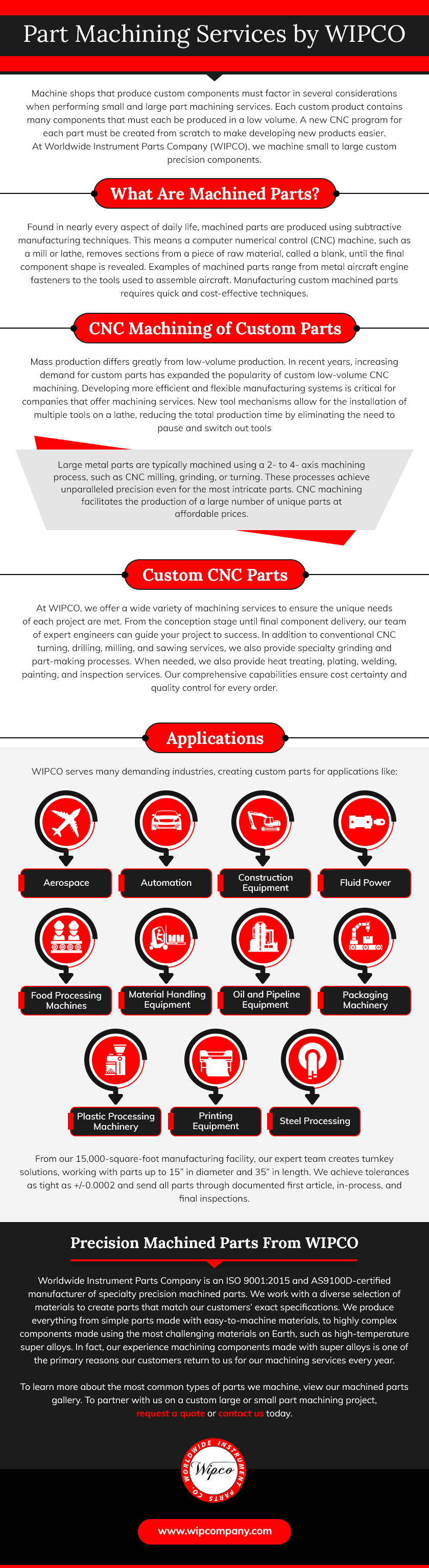

WIPCO serves many demanding industries, creating custom parts for applications like:

- Aerospace

- Automation

- Construction equipment

- Fluid power

- Food processing machines

- Material handling equipment

- Oil and pipeline equipment

- Packaging machinery

- Plastic processing machinery

- Printing equipment

- Steel processing

From our 15,000-square-foot manufacturing facility, our expert team creates turnkey solutions, working with parts up to 15” in diameter and 35” in length. We achieve tolerances as tight as +/-0.0002 and send all parts through documented first article, in-process, and final inspections.

Precision Machined Parts From WIPCO

Worldwide Instrument Parts Company is an ISO 9001:2015 and AS9100D-certified manufacturer of specialty precision machined parts. We work with a diverse selection of materials to create parts that match our customers’ exact specifications. We produce everything from simple parts made with easy-to-machine materials, to highly complex components made using the most challenging materials on Earth, such as high-temperature super alloys. In fact, our experience machining components made with super alloys is one of the primary reasons our customers return to us for our machining services every year.

To learn more about the most common types of parts we machine, view our machined parts gallery. To partner with us on a custom large or small part machining project, request a quote or contact us today.