If your company needs precision machined parts, computer numerical control (CNC) machining services offer one of the most efficient means to get them. CNC technology provides cost-effective and accurate results on parts ranging from simple to highly complex. This guide will outline how CNC machining works, the different machining processes available, and examples of CNC machining use cases in different industries.

What is CNC Machining?

When it comes to manufacturing processes, there are three main categories to choose from:

- Formative manufacturing. Formative manufacturing forms an item from existing material without adding or subtracting anything. For example, liquid injection molding uses injects liquid plastic into a mold, where it hardens into the desired shape.

- Additive manufacturing. Additive manufacturing creates an item by layering materials on top of one another to create a specified shape. Examples include 3D printing and sheet lamination.

- Subtractive manufacturing. Subtractive manufacturing processes begin with a piece of stock material, then cut away material to create the design shape. Computer numerical control (CNC) machining belongs to the subtractive manufacturing category.

While formative and additive manufacturing processes are typically limited to certain types of plastics and polymers, CNC machining is compatible with a much wider variety of materials, including plastics, metals, wood, glass, composites, foam, and more.

As a programmable and automated process, CNC machining follows the same basic steps regardless of the specific part design. These steps include:

- Design. A design engineer creates a digital design file using computer-aided design (CAD) software. This file may go through multiple iterations to make manufacturability modifications and functional design improvements.

- Programming. The CAD design is then converted into a computer-aided manufacturing (CAM) file that can be ready by the CNC machine. This file provides the machine tool with pre-programmed instructions on the required dimensions and cuts needed.

- Machining. A machinist or operator must manually connect the various tooling required for the project. After that, the machining operations themselves are fully automated based on the instructions provided in the CAM file. The machine starts with a block of raw material, typically referred to as the workpiece or blank. Following the uploaded instructions from the digital file, the CNC machine uses various cutting processes to reduce the blank into the desired shape.

Types of CNC Machining Processes

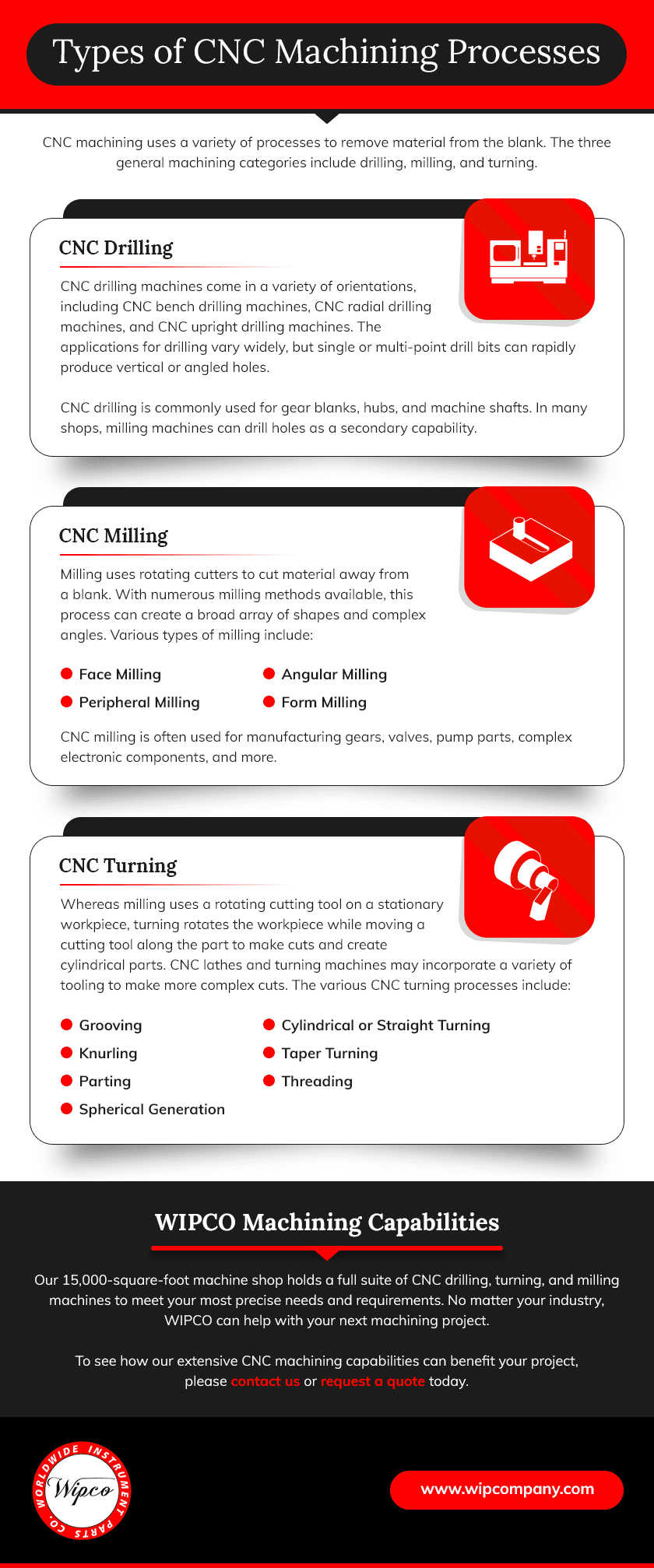

CNC machining uses a variety of processes to remove material from the blank. The three general machining categories include drilling, milling, and turning.

CNC Drilling

CNC drilling machines come in a variety of orientations, including CNC bench drilling machines, CNC radial drilling machines, and CNC upright drilling machines. The applications for drilling vary widely, but single or multi-point drill bits can rapidly produce vertical or angled holes.

CNC drilling is commonly used for gear blanks, hubs, and machine shafts. In many shops, milling machines can drill holes as a secondary capability.

CNC Milling

Milling uses rotating cutters to cut material away from a blank. With numerous milling methods available, this process can create a broad array of shapes and complex angles. Various types of milling include:

- Face milling – Creating flat-bottomed cavities and cutting shallow flat surfaces.

- Peripheral milling – Cutting threads, slots and other cavities, as well as deep flat surfaces.

- Angular milling – Applies the cutting tool at an angle, creating serrations, chamfers, and other angles.

- Form milling – Making spherical or circular shapes using specialized milling cutters. Common when manufacturing complex components.

CNC milling is often used for manufacturing gears, valves, pump parts, complex electronic components, and more.

CNC Turning

Whereas milling uses a rotating cutting tool on a stationary workpiece, turning rotates the workpiece while moving a cutting tool along the part to make cuts and create cylindrical parts. CNC lathes and turning machines may incorporate a variety of tooling to make more complex cuts. The various CNC turning processes include:

- Cylindrical or straight turning. Often the first step in the extended turning process, as straight turning can quickly cut and eliminate large amounts of raw material before applying other turning processes to introduce more intricate, detailed cuts.

- Grooving. A tool gets pressed into the top surface of the turning blank, creating a groove.

- Knurling. Texture gets added, often for increased ergonomics and grip in the final product, by cutting a shallow pattern into the blank.

- Parting. An entire portion of the blank material gets removed by cutting into the turning blank.

- Spherical generation. A blank is reduced to a spherical shape.

- Taper turning. The machine generates a smooth taper by slowly narrowing the diameter of the cut.

- Threading. Threads are added to cylindrical parts, such as screws, by pressing a tool into the blank to form helical grooves.

How CNC Machining is Used

A fully equipped CNC machining facility offers a great deal of versatility. This makes CNC machines a popular choice for applications across all industries that require precision machined parts. Here are just a few examples of common applications for CNC machining:

Prototyping

In advance of full production, a single physical part or small batch of parts is usually produced for testing. A project may go through numerous prototypes as design flaws or functionality issues are identified and corrected, so it’s important to use a cost-effective fabrication method for creating the prototypes. CNC machining produces prototypes without the need to fabricate expensive molds or significantly retool equipment. If the prototype requires changes, the CNC machines simply need new pre-programmed instructions to quickly build another prototype.

Tooling

CNC machining can play an adjunct role in other forms of manufacturing. For example, CNC machines are often used to create complex metal molds used in injection molding processes. A prominent example is plastic injection molding. Many of the tools used in CNC machining were themselves created using a CNC machine.

Full Scale Production

CNC machining produces high volumes of parts with an exceptional degree of accuracy and repeatability. This capability makes it well suited for high-volume production runs and blanket orders.

Custom Parts

CNC machining offers an ideal method for creating fully custom parts. The precision capabilities of CNC machining facilitate a high degree of originality in part designs. CNC machines can handle highly complex cuts and close tolerances, allowing for very strict customization of parts and components.

Many industries rely heavily on CNC machining, including:

- Aerospace. Aerospace engineers and manufacturers need the flexibility to design and produce aircraft parts that are simultaneously complex and precise, such as engine mounts and landing gears.

- Medical. CNC machining frequently meets the medical industry’s demand for very complex device components for heart rate monitors, X-ray machines, and other critical diagnostic and lifesaving equipment.

- Oil and gas. The oil and gas industry relies on CNC machining to produce valves, pistons, pipeline parts, and other safety-critical components.

- Automotive. Automobile designers and manufacturers use CNC machining for prototyping, as well as the production of interior panels, drive axles, cylinder heads, gearboxes and engine blocks.

- Electronics. The electronics industry turns to CNC machining for precise, repeatable parts with a quick turnaround. CNC machining is used for both prototyping and producing small and large components on printed circuit boards, electronics casings and enclosures, heat sinks, and more.

- Commercial. CNC machining has a variety of commercial applications for consumer products, prototyping, packaging, and more.

WIPCO Machining Capabilities

Worldwide Instrument Parts Co. (WIPCO) is an ISO 9001:2015/AS9100D-certified specialty manufacturer of precision machined parts. Our 15,000-square-foot machine shop holds a full suite of CNC drilling, turning, and milling machines to meet your most precise needs and requirements. No matter your industry, WIPCO can help with your next machining project.

To see how our extensive CNC machining capabilities can benefit your project, please contact us or request a quote today.