Quality

Quality

Precision. Consistency. Reliability. Every Part, Every Project.

Our Standard: Excellence at Every Step

At Worldwide Instrument Parts Company (WIPCO), quality is more than an expectation—it’s our identity. For over 25 years, our team has delivered high-precision, tight-tolerance machined components for industries where reliability is critical. From material selection through final inspection, every process is designed to meet or exceed customer and industry requirements.

Worldwide Instrument Parts Company (WIPCO) is an ISO 9001:2015/AS9100D Certified specialty manufacturer of precision machined parts. We machine a wide variety of materials to our customers’ prints and specifications—from simple parts made from easy-to-machine materials, to extremely complex parts manufactured from some of the most challenging materials on the planet, including high-temperature super alloys. Our decades of expertise in machining super alloys is the reason our most tenured customers continue to rely on WIPCO year after year.

Our Commitment to Quality

- Precision Manufacturing: Advanced CNC machining, skilled craftsmanship, and repeatable processes ensure accuracy in every run.

- ISO-Driven Processes: We operate under rigorous standards for documentation, traceability, and process control.

- Experienced Technicians: Our machinists bring decades of hands-on experience with steels, super alloys, aluminum, brass, and specialty materials.

- Customer-Focused Delivery: Quality means delivering parts right—and delivering them on time.

Quality Assurance Process

We hold every part to the highest standards using a comprehensive, multi-stage inspection process.

1. Material Verification:

All raw materials undergo confirmation of dimensions, certifications, and compliance before entering production.

2. Controlled Machining:

Our machinists follow strict machining protocols to ensure consistency, accuracy, and repeatability across every order.

3. In-Process Monitoring:

Dimensional checks and tool wear inspections are performed throughout production to eliminate variation.

4. Final Inspection:

Every component passes through a documented final inspection that includes dimensional verification, surface finish checks, and any customer-specific requirements such as first-article reporting.

5. Documentation & Traceability:

Certifications, material traceability, and inspection reports are available with every job.

6. Continuous Improvement:

We review performance data, customer feedback, and internal metrics to advance our processes and raise our standards year after year.

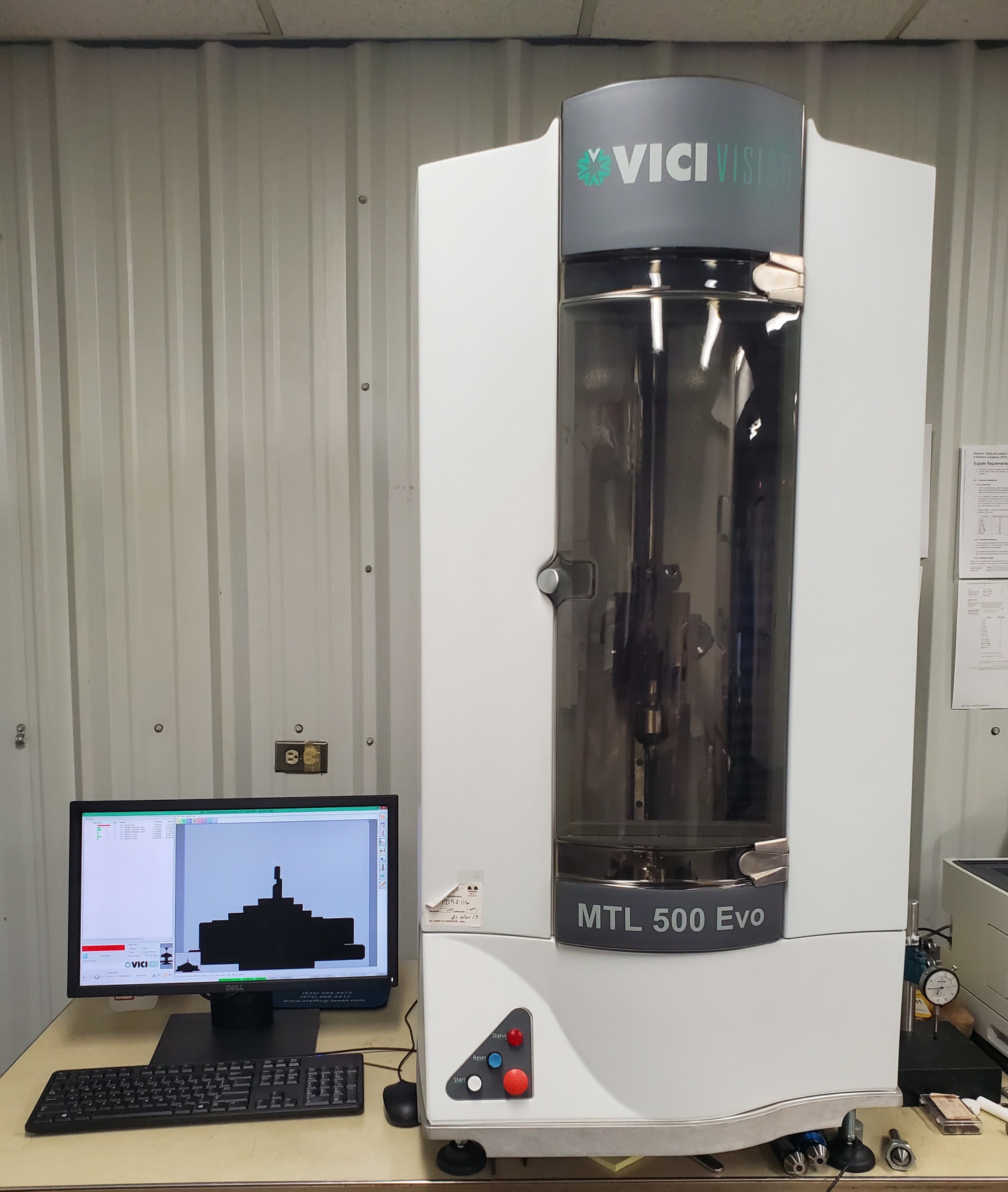

Quality Lab

In our QC lab, all parts go thru 1st article, in-process, and final inspection and are fully documented. Our Zeiss Contura G2 CMM and our Vicci Optical Measuring machines provide computer generated inspection reports that are included in our certification packages for all orders.

Why Customers Trust WIPCO

- Tight-Tolerance Expertise: Capabilities suited for high-precision applications in aerospace, energy, medical, and industrial markets.

- State-of-the-Art Equipment: Modern CNC lathes, mills, and machining technologies enhance speed, accuracy, and consistency.

- Material Flexibility: From stainless steels to high-temperature super alloys, we machine materials many shops avoid.

- Reliable Delivery: Consistent production schedules and clear communication ensure your parts arrive when you need them.

- Long-Term Partnerships: Many of our customers have trusted WIPCO for decades because they know quality is guaranteed.

Quality You Can Depend On

Have a project that requires precision, consistency, and rigorous quality control? Let’s talk.

Request a Quote