Established in 2000, Worldwide Instrument Parts Company (WIPCO) is a specialty manufacturer of precision machined parts. Throughout the years, our establishment has developed within the oil & gas industry along with many other sectors, fine-tuning the way we machine materials to meet specifications no matter how simple or complex. With our CNC machining capabilities, we’re able to produce high-quality parts catered to your exact needs.

Overview of CNC Machining Process

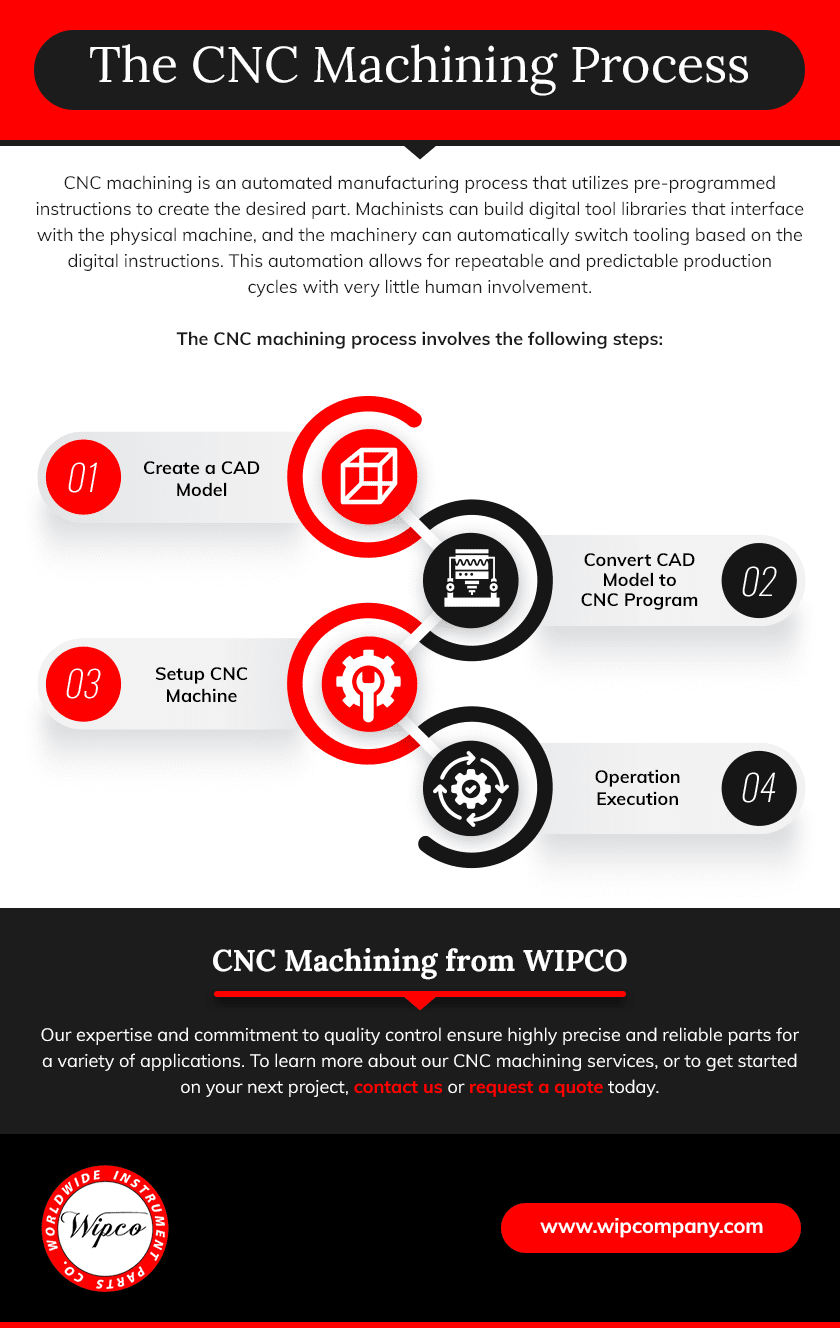

CNC machining is an automated manufacturing process that utilizes pre-programmed instructions to create the desired part. Machinists can build digital tool libraries that interface with the physical machine, and the machinery can automatically switch tooling based on the digital instructions. This automation allows for repeatable and predictable production cycles with very little human involvement.

The CNC machining process involves the following steps:

- Create a CAD model. Engineers create a 3D or 2D design of the desired part.

- Convert CAD model to CNC program. The CAD model design is exported into a compatible file format before it is converted into CNC machine instructions using CAM software.

- Setup CNC machine. Once the file is converted, the machine operator prepares the machine and workpiece.

- Operation execution. The machine operator initiates the machining program, which executes the operation and creates the designed part.

Types of CNC Machining

CNC machining encompasses various types of subtractive machining methods, each of which performs different tasks to produce the desired part. At WIPCO, we offer CNC milling, turning, and drilling services to produce parts based on customer specifications.

CNC Milling

CNC milling is the process of cutting and drilling material with a computer-controlled rotating cylindrical tool that is held in a spindle. There are four major types of milling: face, plain, angular, and form. Each style is used to create a variety of part designs and features such as slots, chamfers, threads, and pockets. CNC Milling is most commonly used to create parts for vehicles, electronic equipment, and other valuables within the medical and military fields.

CNC Turning

CNC turning is the process in which a chuck holds a bar of material, such as plastic or metal, in place. The workpiece rotates on a lathe while a computer-controlled turret with attached tooling cuts the material into the pre-programmed shape.

There are several types of CNC turning processes that can be used together to achieve the desired results. These include straight or cylindrical, grooving, taper turning, knurling, spherical generation, parting, and threading. Common applications for CNC turning include high-precision aerospace parts, dental and medical instruments, automotive parts, and more.

CNC Drilling

CNC drilling is the process of creating holes or other shapes for items such as screws and bolts. Using a spindle, an operator can control the size and diameter to drill a hole. Compared to other CNC machining types, CNC drilling is the simplest to accomplish and often requires less time.

CNC Drilling is commonly used to create plates or shields for items that cover and house important parts.

CNC Machining from WIPCO

No matter how simple or detailed your needs are when it comes to creating precision parts, WIPCO’s CNC machining services can produce high-quality components to fit your every need. Our 15,000 square-foot facility houses various state-of-the-art CNC machinery, including mills, screw machines, and lathes. Our expertise and commitment to quality control ensure highly precise and reliable parts for a variety of applications. To learn more about our CNC machining services, or to get started on your next project, contact us or request a quote today.